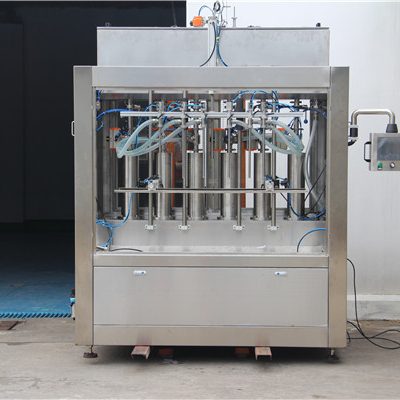

Produktuaren Deskribapena

Olio betetzeko makina automatikoko teknologia berriak

1. Olioa egiteko makina-makina nagusiak PLC eta transduktorearen kontrol automatikoko teknologia hartzen du automatizazio maila altua dutenak.

2. Olioa egiteko makina sistema dinamikoa transmisio ardatzarekiko lotura egonkorra da.

3. Grabitate mikro negatiboaren betetze printzipioak zehaztasuna areagotzen du.

4. Olio-makinaz hornitutako lubrifikazio automatikoko sistema aurreratuak eskuzko ahaleginik ez du eskatzen eta makinen bizitza-bizitza areagotzen du.

5. Olioa egiteko makinaren zarata txikia da eta makina orokorra oso erraza da.

Parametro teknikoak

Model | Garbitu buruak, buruak betetzeko eta estalkitzeko buruak | Ekoizpen ahalmena (orduko botilak 500 ml) | Aplikatu daitekeen botilen zehaztapenak (mm) | Motorearen potentzia nagusia (kw) |

| VKPAK-14-12-5 | 14,12,5 | 4000BPH | 200ml-2500ml D = 55-110mm H = 150-310mm | 1.5 |

| VKPAK 16-16-5 | 16,16,5 | 5500BPH | 2.2 | |

| VKPAK 24-24-6 | 24,24,6 | 8000BPH | 2.2 | |

| VKPAK32-32-8 | 32,32,8 | 10000BPH | 3 | |

| VKPAK40-40-10 | 40,40,10 | 14000BPH | 5.5 | |

| NAPCK50-50-12 | 50,50,12 | 17000BPH | 5.5 | |

| VKPAK60-60-15 | 60,60,15 | 20000BPH | 7.5 | |

| VKPAK72-72-18 | 72,72,18 | 25000BPH | 7.5 |

Xehetasunak

Mota: Betetzeko makina

Egoera: Berria

Aplikazioa: Olioa

Pakete mota: Botilak

Enbalatzeko materiala: Egurra

Kalifikazio automatikoa: automatikoa

Gidatutako Mota: Elektrikoa

Tentsioa: 380v

Potentzia: 7,5kw

Jatorrizko lekua: Shanghai, Txina (kontinentala)

Marka izena: VKPAK

Model Number: VKPAK32-32-8 New technology automatic oil filling machine, VKPAK32-32-8

Neurria (L * W * H): 4600x1800x2650mm

Pisua: 9000kg

Ziurtagiria: ISO, CE, SGS, ISO, CE, SGS

Saldu osteko zerbitzua: Atzerrian zerbitzuko makineria eskuragarri dauden ingeniariak

Izena: Olio betetzeko makina automatiko berria

Edukiera: 20000BPH

Motor-potentzia nagusia: 7,5kw

Aplikatzeko botila: D = 55-110mm H = 150-310mm

Bermea: 2 urte

Makinaren materiala: SUS304

Enbalatzea eta entrega

Paketearen xehetasunak:

Olio betetzeko makina automatikoarentzako zurezko estandar estandarra

Bidalketaren xehetasuna:

45 egun Teknologia Berria olio betetzeko makina automatikorako

zehaztapenak

Olio betetzeko makina automatikoko teknologia berriak

1. capacity:4000-25000BPH(500ml)

2. guarantee:2 years

3. high quality, good price

An 8000BPH (bottles per hour) automatic coconut oil filling machine line is a high-speed bottling system designed for the efficient and accurate filling of coconut oil into containers. This type of filling machine typically consists of several components, including an unscrambler, bottle washing machine, filling machine, capping machine, labeling machine, and packaging machine. The overall production line is designed to work together seamlessly to achieve a high rate of production while ensuring that the quality and accuracy of the fill is maintained.

The specific features and specifications of an 8000BPH coconut oil filling machine line may vary depending on the manufacturer and the intended application, but some common features include:

High-speed production: This type of machine is designed to fill containers at a high rate of speed, with the capability of filling up to 8000 bottles per hour.

Precision filling: A sophisticated control system and precise filling nozzle ensure that each bottle is filled to the exact volume specified, with minimal waste.

Adaptability: Many coconut oil filling machine lines are designed to be adaptable to different bottle sizes and shapes, allowing for easy changeover and minimal downtime.

Quality control: A variety of sensors and inspection systems are integrated into the production line to ensure that the filling and capping processes meet the necessary quality standards.

Ease of use: The machines in a coconut oil filling machine line are typically designed with user-friendly controls and intuitive operation, making them easy to set up and operate.

Overall, an 8000BPH automatic coconut oil filling machine line is a reliable and efficient solution for bottling coconut oil, with the capability of achieving high production rates while maintaining a high level of accuracy and quality control.